In June 2023, two significant developments have greatly impacted India’s mineral and rare earth sector. Firstly, India became a member of the Mineral Security Partnership (MSP), with the goal of ensuring responsible production, processing, and recycling of critical minerals. This partnership aligns with the aim of maximising economic benefits from international geological resources to support India’s growth in the green and renewable energy sector. Secondly, the Indian government has compiled a list of 30 critical minerals, setting the stage for strategic planning to mitigate supply chain risks and meet the demands of Industry 4.0 and other economic needs.

While these developments are commendable, India needs to go beyond them to cultivate sustainable self-reliance in minerals and rare earths. Additional measures must be considered to enhance the sector’s resilience and long-term viability.

READ I Sustainability: An enabler for just economic transition

A supportive critical minerals ecosystem

To achieve self-reliance in critical minerals, several vital aspects need focused attention. First and foremost, conducting a comprehensive assessment of the country’s mineral deposits, rare earth element reserves, and critical mineral resources is imperative. This evaluation should ascertain the availability, quantity, quality, and economic viability of these resources for potential exploitation.

Secondly, substantial investment in research and development (R&D) initiatives is essential. This investment should be directed towards advancing metallurgy, mineral extraction, processing, and refining techniques. India’s membership in the Mineral Security Partnership (MSP) can facilitate collaborations between Indian research institutions and counterparts from the 14 member countries, fostering innovation and the creation of cutting-edge technologies.

Thirdly, it is crucial to bolster the educational infrastructure by promoting specialised courses and degree programs in metallurgy, minerals, and related fields. The establishment of training centers and apprenticeship programs will be pivotal in nurturing a skilled workforce capable of handling advanced mining and processing technologies. China’s success in rare earth mineral mining and processing can be attributed, in part, to its focus on developing world-class institutions in these domains.

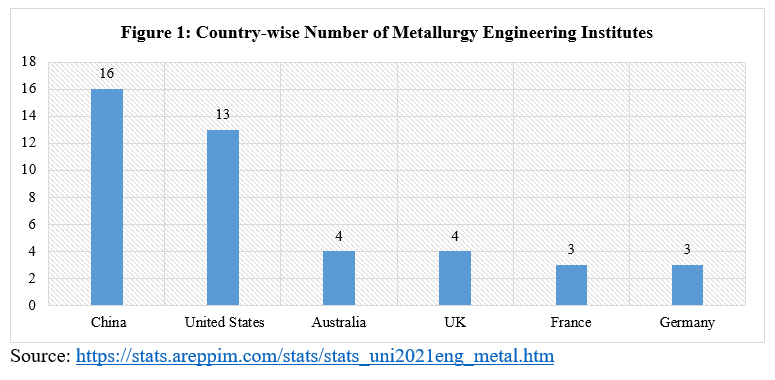

Interestingly, as per AREPPIM’s 2021 database, India lacks any metallurgy engineering institute among the top 50, while China and the US boast 16 and 13 institutes, respectively. This underscores the importance of prioritising the establishment of prestigious metallurgy engineering institutes in India to bridge the gap and cultivate excellence in the field.

The absence of expertise in metallurgy sciences directly hampers the development of a knowledge base for critical industries, including jet-engine technology, semiconductor chips, photovoltaic cells, airplanes, and shipbuilding. Figure 1 below illustrates the number of metallurgy engineering institutes by country, with China dominating the top 5 positions among a total of 16.

The role of metallurgical engineering in India’s critical minerals sector cannot be overstated. It plays a pivotal role in various aspects, ranging from extraction and processing to refining and utilisation of critical minerals. Highly trained metallurgical engineers contribute to efficient mineral extraction, mineral beneficiation, metallurgical processing, process optimisation, alloy development, recycling, quality control, technological advancements, and sustainable mining operations.

Building a comprehensive infrastructure

To further enhance sector development, the establishment of a robust infrastructure supporting the entire value chain of metallurgy and mineral industries is crucial. This involves creating efficient transportation networks for smooth movement of raw materials and finished products, constructing modern mining facilities, and setting up state-of-the-art processing and refining plants.

Furthermore, diversifying supply chains and reducing dependence on a single market is paramount. To achieve this, cultivating strong trade relationships with other countries is essential. For instance, minerals like cobalt (found in Congo and Australia), lithium (available in Argentina, Bolivia, and Australia), and nickel (abundant in Indonesia, Australia, and Russia) require strategic agreements and enhanced diplomatic outreach to ensure access to these critical resources.

By prioritising metallurgical engineering, establishing robust infrastructure, and cultivating strategic trade relationships, India can strengthen its position in the critical minerals sector and guarantee a steady supply of these resources for various industries and technological advancements.

Achieving sustainable self-reliance

To establish sustainable reliance on critical minerals, creating an investor-friendly environment that attracts foreign direct investment (FDI) in the mineral and metallurgy sectors is crucial. This can be accomplished by offering incentives such as Production Linked Incentives (PLI) in key sectors like electronics and semiconductors, overseas mine acquisitions, negotiating contracts in rupees (Egypt, Argentina), providing case-based tax breaks, and implementing streamlined regulations. Encouraging partnerships with international mining and metallurgical companies is also essential to leverage their expertise and capital, especially in areas where local companies lack experience.

To facilitate systematic investment, the development of a comprehensive policy and regulatory framework is of utmost importance. This framework should support the growth of the metallurgy and mineral sectors, ensuring stability, transparency, and consistency in policies related to mining, trade, taxation, and environmental regulations. Reducing bureaucratic hurdles and eliminating unnecessary red tape is essential to sustain the enthusiasm and engagement of private players in the industry.

Moreover, promoting sustainable and responsible mining practices is vital to minimise environmental impact and uphold social responsibility. Rigorous yet business-friendly regulations should be formulated and enforced to address environmental protection, land reclamation, and worker safety. This approach will strike a balance between industrial growth and environmental preservation.

In addition, fostering a business ecosystem that encourages adherence to international standards and certifications will enhance India’s reputation as a reliable player and business partner in the global market. Encouraging businesses to meet and surpass international standards ensures that ethical practices and sustainability are prioritised throughout the entire value chain.

By establishing an investor-friendly environment, crafting comprehensive policies, promoting sustainable mining practices, and emphasising adherence to international standards, India can lay a solid foundation for sustainable reliance on critical minerals. This approach will not only attract foreign investment but also foster responsible business practices, contributing to both economic growth and environmental stewardship.

(Dr. Ram Singh is Professor, Export Import Procedure & Trade Logistics, at Indian Institute of Foreign Trade.)