Exports face container crisis: India’s export sector is facing mounting pressure as soaring freight costs and a severe shortage of shipping containers threaten to undermine its trade ambitions. Recent disruptions in key maritime routes, such as the Red Sea, along with port congestion and logistical inefficiencies, have driven up shipping costs and stretched container availability to breaking point. Small and medium enterprises, which rely on affordable and efficient logistics, are bearing the brunt of these challenges. With rising container prices and shipping delays, exporters are struggling to stay competitive in global markets, jeopardizing India’s broader economic goals. To safeguard its export momentum, India must urgently scale up domestic container production and reduce its dependence on foreign shipping lines.

The Union government is planning several steps to mitigate the container shortage and ease trade disruptions. A key part of this effort includes expanding the Shipping Corporation of India’s container capacity by purchasing additional second-hand vessels and launching a new large container ship to operate regularly. The government has also moved to reduce costs associated with loading and handling containers, with state-owned Container Corporation of India offering significant cuts in storage fees. Simultaneously, faster clearances at major ports, such as Jawaharlal Nehru Port Authority, are being implemented to reduce turnaround times. These measures aim to not only improve container availability but also bring down shipping costs, offering relief to exporters in the coming months.

READ I Trade deficit surges on rising gold imports, global headwinds

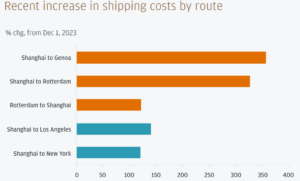

Freight costs on the rise

Freight costs for Indian exporters have more than doubled in recent times. For instance, shipping goods to key markets such as Europe and the United States has become significantly more expensive, with rates for a 40-foot container reaching around $4,775 in 2024, compared with just $1,420 in 2019. This is a staggering increase, driven by a combination of global supply chain disruptions and logistical inefficiencies. The recent delays at Indian ports, largely caused by congestion at major transshipment hubs like Singapore, have only exacerbated the problem.

One major factor contributing to the rise in freight costs is the disruption in the Red Sea region, a critical maritime route for global trade. With ongoing geopolitical tensions in this area, the costs of shipping goods have spiraled, putting further pressure on exporters. Compounding these issues is the US-China trade war, which could escalate in the coming months, triggering further instability in global trade routes and inflating freight rates.

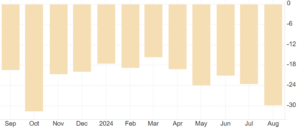

India trade balance ($ billion)

The vulnerability of Indian exporters to these freight cost hikes is largely due to the country’s heavy reliance on foreign shipping lines. A staggering 90-95% of India’s total cargo is transported by foreign carriers such as Maersk, MSC, and COSCO. This dependence not only inflates costs but also limits India’s ability to control shipping schedules and access, making its export sector highly susceptible to international market fluctuations.

Container crisis snowballs

The global shortage of shipping containers, first triggered by the COVID-19 pandemic, remains a significant challenge for India. As the world grapples with recovering from the supply chain shocks of the pandemic, containers remain in short supply. While there are rumors of China hoarding containers to maximise its exports, the issue seems to be driven more by broader logistical inefficiencies than deliberate stockpiling. Nevertheless, India’s over-reliance on Chinese-made containers has made the country particularly vulnerable to these shortages.

India produces between 10,000 and 30,000 containers annually, a meager output compared to China’s production of around 2.5 to 3 million containers per year. This leaves India with less than 1% of the global market share for containers, making it reliant on imports to meet demand. Furthermore, the cost of manufacturing a 40-foot container in India, at around $3,500 to $4,000, is significantly higher than China’s cost of $2,500 to $3,000. This price disparity further discourages local production and perpetuates India’s dependence on foreign suppliers.

Impact on Indian exporters

The consequences of rising freight costs and container shortages are particularly severe for small and medium enterprises (SMEs) that rely on cost-effective shipping to remain competitive in global markets. Many of these businesses are already grappling with other challenges, such as navigating complex export regulations, meeting stringent product standards, and competing with exporters from developed nations that benefit from government subsidies. The added burden of higher shipping costs and container scarcity could push many SMEs to the brink, threatening jobs and economic growth.

Additionally, the delays caused by port congestion and the limited availability of containers extend transit times, increasing the risk of missing delivery deadlines and losing key customers in international markets. Exporters in sectors such as textiles, electronics, and agricultural products are particularly vulnerable, as these goods are time-sensitive and require efficient logistics to maintain market share.

Strengthening domestic capabilities

To mitigate these challenges and secure India’s position in global trade, it is essential to focus on expanding domestic container production and reducing dependence on foreign shipping companies. Several key strategies can help address these issues:

Expand container production: India must scale up its container manufacturing capacity by investing in infrastructure and offering financial incentives to producers. Emerging production hubs in Bhavnagar (Gujarat) and Chennai (Tamil Nadu) need to be fully supported to meet domestic and global demand. By increasing local production, India can reduce its reliance on imports and mitigate the impact of global container shortages.

Promote use of Indian-made containers: The government should introduce policies that incentivise exporters to use domestically produced containers. This could include preferential treatment for exporters who use Indian-made containers, provided these policies align with international trade regulations.

Strengthen domestic shipping firms: India needs to reduce its dependence on foreign shipping lines by bolstering its domestic shipping industry. This can be achieved by providing subsidies, tax breaks, and other incentives to Indian shipping companies to help them compete with global giants. The development of a robust domestic shipping sector will not only lower costs but also increase control over shipping schedules and logistics.

Improve port infrastructure: Accelerating the Sagarmala project, which aims to modernise India’s ports, is critical to ensuring that goods can be shipped efficiently and cost-effectively. Better port infrastructure will not only support the increased production of containers but also streamline logistics, reducing delays and lowering costs.

India’s export sector is facing rising freight costs and container shortages, placing immense pressure on businesses, particularly SMEs, threatening to derail the country’s export growth. To safeguard its position in the global trade landscape, India must urgently invest in domestic container production, strengthen its shipping industry, and modernise port infrastructure. By taking these steps, India can reduce its vulnerability to global supply chain disruptions and enhance its competitiveness in international markets. The future of Indian exports depends on decisive action today.