Industrial policy is a document that defines the role of government in industrial development, specifying the role of the public and private sectors, small industries, and foreign capital. It also lists the measures to be taken to reach the defined goals. As the objectives of the policy change with time to meet the current and future needs of society, the policy ought to be redefined and formulated after an appropriate time gap.

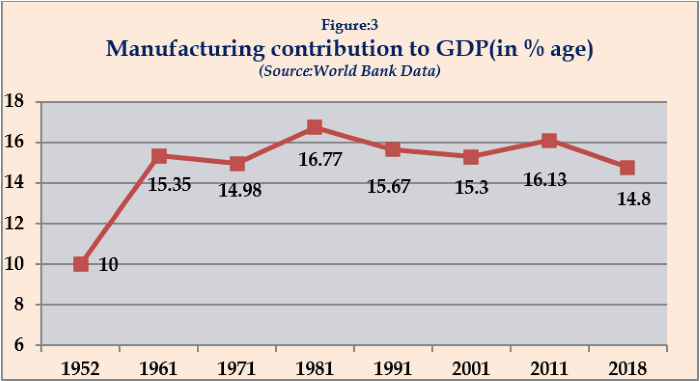

In India, the industrial policy was first pronounced in 1948 with the government adopting a mixed economic model for development with a strong bias towards the public sector. This policy was continued barring some incremental changes till 1991 when the Indian economy began its journey on the path of reforms and liberalisation. Although it rescued the economy from imminent collapse, certain drawbacks in the policies led to asymmetry in the economy and attracted criticism. In particular, the manufacturing sector in India was the casualty of the liberalised imports.

After a gap of 25 years, the government realized the need for formulating a new industrial policy. In April 2018, the Rajya Sabha was informed by the minister of state for commerce and industry that the government is in the process of formulating a new industrial policy that envisions creation of a globally competitive Indian industry and the objectives inter alia include promoting emerging technologies, build an innovation driven economy, promote high quality industrial infrastructure, provide enhanced access to affordable capital for MSMEs, strengthen linkages between trade and manufacturing, and enhance skill development and making doing business easier. Again, in June 2019, the commerce and industry minister informed the Lok Sabha that the policy is likely to be finalised shortly.

READ I Targeted incentives can boost manufacturing sector, revive MSMEs

Structural transformation trends in India

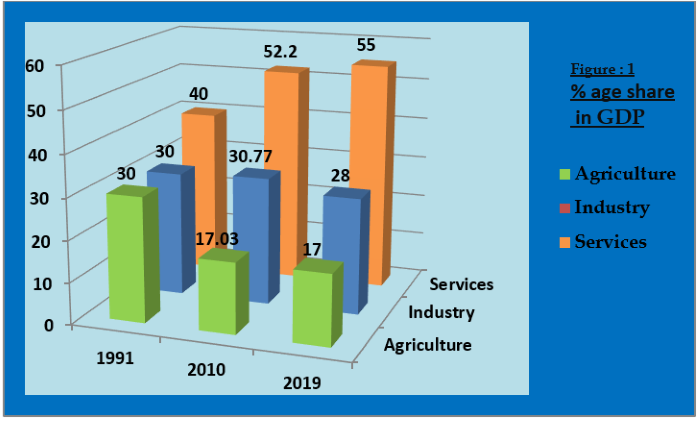

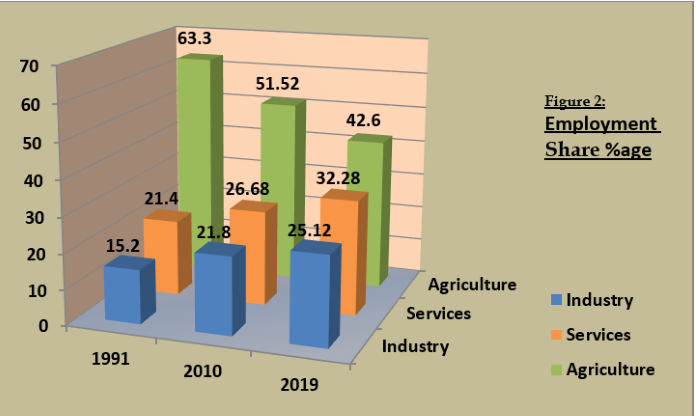

Since the reform process began in 1991, a gradual decline in the contribution of agriculture sector to India’s GDP was noted till 2010. This fall of 12% in GDP contribution from agriculture nearly after two decades of reforms was almost entirely absorbed by the services sector. However, in terms of shift in workforce, the exodus from the agriculture was almost equally absorbed by the industry and services sector.

(Source: World Bank Data)

It was during the 2008-12 period that the shifting of workforce from agriculture was highest, amounting to almost 5%. It was not merely a coincidence that the period 2006-12 witnessed a healthy growth rate of 9.5% in India’s manufacturing sector. The subsequent seven-year period saw a slowdown in the transition of labour from agriculture with less than 1% change during which the growth in the manufacturing sector declined to 7.4%. The importance of the manufacturing sector can be realised from the fact that with around 7% of the total workforce engaged, it has a share of 16% in GDP; on the other hand, the agriculture sector contributes around 17% to the GDP and engages a whopping 42% of the total labour force.

Broadly, the increasing share of the service sector in the overall GDP of the country is a welcome sign that India is a fast-developing economy. However, the uneven distribution of GDP among sectors and corresponding employment figures hints at a disturbing trend, and the asymmetry in the GDP structure needs to be corrected as a medium/long-term goal using suitable policy instruments.

READ I India’s fledgling e-commerce industry needs a robust policy framework

Why a new industrial policy

In India, the economic growth pattern seen in the last three decades is somewhat unconventional as it has been primarily driven by the services sector whereas, in developing economies, the growth of industry precedes the expansion in the services sector. Nevertheless, the overall growth did help in creating employment opportunities and contributed to poverty reduction to a considerable extent. It, however, largely failed in bringing structural transformation into the economy.

Both the UPA and the current NDA regimes realised the importance of the manufacturing industry for employment generation and economic growth, and launched National Manufacturing Policy (NMP), and make in India, respectively to achieve the goal of a higher share for manufacturing sector in GDP to 25% in 10 years, however, the desired objectives were not achieved. The recently introduced Production Linked Incentive (PLI) scheme for 13 sectors is an effort to make products for the domestic market more competitively priced, reduce dependence on imports, and upscale production volume by offering financial incentives of 4-6%. However, it is too early to judge its efficacy in correcting deficiencies in the manufacturing ecosystem and help domestic manufacturers become a part of the global value chain.

Addressing the concern of sluggish growth in the manufacturing sector has to be the core of the new industrial policy. The structural transformation of the economy witnessed after the economic reforms skipped the first stage that is labour moving out of agriculture into manufacturing was very limited. Unlike a developed economy which relies on the services sector for growth, in a low or medium-income country, the labour first moves from low productivity, low wage sector to high productivity, high wage sector. However, the role of the manufacturing sector, even in a developed economy should not be underestimated as it is the innovation and productivity increase in manufacturing which creates opportunities for expansion of services.

In India, the development process failed to change the occupational structure of labour force. Was it due to the sluggishness in the manufacturing sector or the fast growth of services? This trend witnessed in the Indian economy is both peculiar and tragic since it has not been accompanied by a corresponding increase in employment. This is one reason why despite enhancement in the size of the economy, India still lags in achieving inclusive growth; another being perpetual low productivity in the agriculture sector.

The services sector cannot absorb a large number of low and semi-skilled workers from the farm sector whereas manufacturing has the appetite for labour with limited skills. Moreover, the services sector does not have the same level of employment elasticity of growth which the manufacturing sector offers. Thus, despite a strong government push, liberalised investment policy, sound FDI inflows, improved ranking in ease of doing business, and availability of a large market, the growth in the manufacturing sector remained insignificant. Is the failure a result of an absence of a manufacturing culture, shift of focus and talent to the IT sector, or lack of government intervention through a holistic industrial policy?

READ I Cryptocurrency rush: Bitcoin rally forcing the sceptics to rethink

Impact of industrial policy in other economies

In India, industrial policy is often mistaken as a tool available with the government for regulating the industry, or a mechanism for granting industrial approval. It is misconstrued since industrial policy in independent India was administered through the Industrial (Development and Regulation) Act which was more or less a kind of dos and don’ts for the industry. Given this background, many believe that it would be better if the industry is left alone to perform without government intervention.

The most common apprehension is the notion that bureaucrats are not capable of understanding businesses and the rules and regulations framed by them may lead to a more cumbersome business environment and misplaced investment decisions. In cases where disbursals of subsidies or government procurements are involved, the chances of corrupt practices cannot be ruled out. But, the 2008 global recession forced this realisation that an unregulated market can lead the economy to a chaotic condition which particularly hits hard those at the bottom of the ladder including the small industries. The chronology of industrial development right from the eighteenth century in the US, the largest practitioner of the free-market economy, shows that it actively followed industrial policies often sector-specific which promoted and protected domestic industries through subsidies, loan guarantees, government procurement contracts, underwriting high-risk investments like R&D, promoting investment in areas having potential for export, and special tax rebates to gain international competitiveness.

In the twentieth century, to counter the effects of the Great Depression of 1930s, the US promulgated the National Industrial Recovery Act (NIRA) which offered subsidies, protection from foreign competition, and support via public procurement to targeted industries. The US has a history of providing support to its industry and a major part of the government support went to manufacturing industries like Boeing, GM, Tesla Motors, and the American steel industry, though the US government never proclaimed any industrial policy as such.

To counter the rising competition from Japan and South Korea in the field of automobiles and electronics in the 1970s, the US established the National Center for Manufacturing Sciences (NCMS), a cross-industry technology development consortium dedicated to improving the competitiveness and strength of the North American industrial base. In recent times, after the Great Recession of 2008, the enactment of the American Recovery and Reinvestment Act (ARRA) for federal spending intended to create new jobs and recover jobs to compensate for a slowdown in private investment was another example of the US government intervention and it included $120 billion for spending on infrastructure alone.

The rise of China from a low-income developing country in the 1970s to achieving the status of the Factory of the World and a leader in innovation is the result of a well-calibrated industrial policy with strong government support. Even after securing the top manufacturer status globally with a share of 28.7% of the total global output, China is striving to move further up the global value chains (GVCs) in high-tech areas and become a technology leader by 2049. It has formulated long-term strategies such as Made in China 2025 (MIC2025) for sustaining and consolidating its leadership position while looking for new sources of growth.

The most noticeable feature of MIC2025 is the government is seeking to align its development goals with the commercial goals of the private sector, providing large financial support both from central and provincial governments.

Towards a new industrial policy for India

The history of industrial economies establishes that the structural transformation in the economy has helped in alleviating poverty and inequality, and the change was accomplished using instruments under some form of industrial policy. Market forces left alone cannot transform low-productivity and low-value-added economic activities, without strong government intervention. The growth of East Asian economies provides good examples of the crucial role that industrial policy can play in structural transformation.

In 2017, DPIIT, the administrative department for Industrial policy, brought out a discussion paper inviting comments and suggestions for drafting a New Industrial Policy. While reviewing the status of industrial growth since 1991, the discussion paper identified a lack of quality industrial infrastructure, restrictive labour laws, complex and time taking business processes, slow technology adoption, low productivity, shrinking global demand, and inadequate investment in R&D as shortcomings that restrained the industrial growth. To overcome the deficiencies in the economy arising from the flaws in the previous policies and meet the new challenges of the twenty-first century, the following areas are identified as those requiring special consideration from the policymakers:

Promoting Research and Innovation: Apart from providing tax and other fiscal incentives to individual MSME units and setting up common testing /investigation facility in identified industrial clusters to infuse a culture of research and innovation, it is suggested that the new industrial policy needs to be aligned with National Research Foundation (NRF) proposed under the New Education Policy (NEP) to meet the requirement of both academia and industry. Identification of a goal by industry and sharing the same with university researchers to be addressed by a joint research team should be institutionalised. Presently, lack of a structural mechanism for the two sides to exchange views is a major hurdle.

Productivity enhancement: In most businesses, the cost of workforce hiring represents the largest outgo, hence, labour productivity is of foremost importance for achieving competitiveness in tough international markets. Besides, encouraging enhancement in the productivity in the existing production line using new technological tools like robotics, IIoT, additive manufacturing etc would result in saving in cost, time, and resources. The new industrial policy should suggest an institutional mechanism and skill development model, preferably in PPP mode, in partnership with Ministry of Skill Development and Entrepreneurship and in consultation with private sector to ensure development of relevant skills in workforce. For MSME units, the implementation of productivity improvement programme should preferably be clubbed with clusters for cost saving and also since similar technology tools are needed of for similar industries.

Incentivising investment in green-field manufacturing: Despite impressive FDI inflows in the last decade, the amount of FDI in manufacturing sector is well below the expectations and it only demonstrates modest interest shown so far by foreign investors in India’s manufacturing ecosystem. To overcome the hesitations of the foreign and domestic investors, the proposed new industrial policy should permit full tax exemption for 5-10 years to companies making green-field investment beyond a specified limit under the policy. Those setting up manufacturing units for high tech products like IC chips, High Precision CNC cutting machines, Aero space parts, may be additionally offered rebate in corporate tax.

Upgradation of industrial clusters: Identifying at least 10 industry clusters each year based on turnover, employment and export potential for improvement of logistics, quality testing labs, road and rail networks for quicker transportation to nearest ports and also to domestic markets, should form a core part of the policy. Automobile, Pharma, Textiles, Food Processing, and Electronics hardware are listed as some of the priority sectors for cluster development.

Focus on MSME: With around 31% of total 63 million MSME units engaged in manufacturing activities having a share of 33% of the country’s total manufacturing gross value output (GVO) and employing 36 million people (32% of all MSME employment), it has the potential to push the growth rate, and addressing the unemployment problem. However, MSMEs face challenges like timely credit, logistics, meeting standards of global markets etc and needs support of an eco-system to facilitate their integration with the global value chain. Creating and strengthening such a system with improved connectivity, easy credit access, logistic and technology support for these enterprises would accelerate India’s transition from an agrarian to an industrialised economy.

GVC oriented policy: In general, any policy initiative which encourages manufacturing activities is good for linking local units with international production chains. Identifying sectors having strong GVC linking capability and then strengthening areas such as mutual recognition of standards with countries having FTAs, less trade barriers, and faster customs processes, robust IPR protection mechanism, improved logistics, and improving the general business environment for investment in manufacturing are some of the measures suggested under the new industrial policy. This kind of holistic approach will require deeper engagement between various government bodies.

Addressing climate change challenges: Climate change has affected the planet both economically and socially during the last 50 years and the developing countries are the ones most affected. Since the first industrial revolution, advanced economies had been the largest source of greenhouse gases in the atmosphere, and coincidently, it is the developed countries wherein the know-how to mitigate climate change impacts lie. Thus, the new industrial policy should emphasise a low carbon and energy efficient industrialisation target and define terms like green technology, green goods, and green FDI for incentivising as these contribute towards achieving targets of green growth. Although it may cost extra, however, such new products and technology create new business opportunities as well.

The goals under the policy for industrial development have to be consistent with the level of competency to absorb technical knowhow, skilled manpower, and available resources, both material and financial. It is equally vital not to be overambitious in the identification of sectors for development as it may result in waste of scarce resources.

(Krishna Kumar Sinha is an industrial policy and FDI expert based in New Delhi. His last assignment was as an industrial adviser in the department of industrial policy and promotion, DIPP, currently known as DPIIT, under the ministry of commerce and industry of the government of India.)

Krishna Kumar Sinha is an industrial policy and FDI expert based in New Delhi. His last assignment was as an industrial adviser in the department of industrial policy and promotion, DIPP, currently known as DPIIT, under the ministry of commerce and industry of the government of India.