The lush green surroundings of mining areas in India are marked by a complex array of natural and artificial topographies, each shaped by the enticing geological features that draw the attention of the mining industry. The waterbodies, streams, and rivers that flow beside mining locations symbolise the fragile balance between nature’s gifts and industrial activities. The mandate of the Union and state governments for the operation of modern effluent treatment plants by the mining industry reflects a serious effort to tackle water contamination and pollution, a vital yet complex challenge.

Despite these initiatives, challenges persist, particularly in zones excluded from treatment protocols, underscoring deficiencies in our collective environmental stewardship. Water is used by the mineral industry for the transportation and processing of ore, for the separation of minerals, for controlling dust, equipment washing, and human consumption. Mining companies store water in dams or mining voids to provide a stable supply for their operations.

READ I Demographic dividend: The make-or-break decade for India

Advances in water management

Our engagement with ETP implementation, while harnessing water from adjacent areas, yielded an enlightening discovery: the water we reintroduced to the environment after treatment was of a superior quality than that we extracted. This revelation led us to an innovative strategy where treated water is repurposed for domestic consumption in our mines and colonies, thereby mitigating the pressure on local aquifers and setting a precedent for sustainable water management in industrial activities.

This strategy is reflective of broader initiatives like the Namami Gange project, aimed at revitalising water bodies not solely through direct intervention but by addressing the upstream sources of contamination. By reducing the discharge of polluted water into the Ganga, the task of cleansing the river becomes inherently more manageable. Applied to mining operations, this strategy highlights the critical importance of understanding the local hydrological cycle, to reduce our environmental footprint.

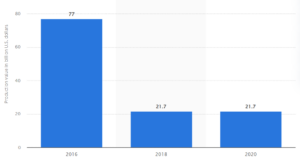

India: Value of mineral production (in $ billion)

Concern and knowledge over water resources have increased to an extraordinary degree which have been brought about by events such as Shimla and Chennai running low on water and the Composite Water Management Index made public in June by NITI Aayog predicting that 21 large cities could run out of groundwater shortly. India is currently found as “water-stressed” and on the verge of becoming “water scarce” (TERI, 2018). Water scarcity was brought to attention at the 1992 Dublin Conference, where it was suggested to treat water as an economic good.

Mining industry and water management

The concept of virtual water extends this narrative, demonstrating how regions with scarce water resources manage their needs by importing water-intensive products. From Middle Eastern countries importing grapes to dairy farms sourcing fodder on an international scale to China exporting almost all its water through “Made in China” products, the global trade in virtual water illustrates the interconnected nature of our water usage. Due to the influx of water-intensive products, 160 out of 195 economies globally are “net virtual water importers”. In recognition of this, we have been prompted to reassess the water intensity of our ferroalloys value chain, aiming to lessen the environmental impact of our products on a worldwide scale.

The complexity of air pollution affecting Delhi is often tied to the groundwater policies in Punjab, and the incongruous cultivation of water-intensive crops in unsuitable areas like the cultivation of sugarcane in Maharashtra, serve as stark indicators of the systemic nature of water stress across the country. These instances reveal the necessity for a comprehensive understanding of water management, one that considers the historical and geographical nuances of water bodies. As suggested by environmental experts, solutions to pollution prevention and water treatment must be tailored to the local water bodies, ensuring that interventions are both effective and sustainable.

Tech innovations and policy enhancements

Our journey towards enhanced water management has been characterised by technological innovation. Collaborating with startups like FluxGen has enabled us to leverage Internet of Things (IoT) technology, facilitating real-time monitoring and management of water use across our operations.

This initiative helped us to bridge the gap between efficient water resource utilisation and high-scale ore production by conducting a water audit and analysing virtual water consumption in the mine-to-mill value chain. Then, advanced technology is leveraged to automate and scale up daily operations, reducing the burden on manpower and conserving water resources. From mining sites to processing facilities, the deployment of sensors and digital flow meters regulated by a control panel offers a holistic view of our water footprint, pinpointing avenues for reduction and efficiency gains. Starting from data collection of water inflow and outflow from each process, quantitively analysing the usage data through proper monitoring, and then the creation of a water balance diagram led us to conclusions about the effectiveness of the water management system and its environmental impact.

The significance of these initiatives is profound, achieving water intake reductions of up to 26% in some locales, while also cultivating a culture of sustainability within our operational ethos. Our cloud-based system, currently utilising IoT, is set to incorporate artificial intelligence (AI) to further advance our water conservation efforts. The anticipated benefits, ranging from leakage detection to enhanced data analytics, envision a future where water management in mining is both sustainable and innovative.

Establishing a strategic framework aimed at sustainable water use, not only highlights the potential for significant enhancements in water conservation within the mining industry but also sets a precedent for the broader industrial sector. The emphasis on comprehensive water audits, the integration of cutting-edge technologies for data-driven decision-making, and the development of robust benchmarking mechanisms collectively enable a forward-thinking approach to environmental stewardship and resource management. Further, it offered a blueprint for operational adjustments and thereby adoption of best practices in water management.

Reflecting on the Bhagavad Gita, where Krishna posits, “I am the essence of water,” we are reminded of the intrinsic value of this resource. Our endeavours, though nascent, represent strides towards respecting and harmonising with the natural world, ensuring that the mining industry can coexist sustainably with our environmental heritage.

Government regulations play a crucial role in incentivising and enforcing water use efficiency in the mining industry. Without clear standards for water use, increasing industrial water productivity will not be possible and thus there is a requirement for building up guidelines with proper benchmarks for creating a roadmap for achieving increased water use efficiency. Govt of India has taken the right step by setting up the Bureau of Water Use Efficiency (BWUE) under the scheme of the National Water Mission.

As we progress, the lessons gleaned and the technologies adopted chart a course for the industry, demonstrating that through innovation, collaboration, and a deep-seated reverence for our environmental legacy, sustainable water management in mining is not just feasible but very essential. The path ahead demands a commitment to ongoing improvement, an openness to novel solutions, and above all, a collective resolve to safeguard and cherish our planet’s most vital resource.

The author is Executive Incharge, Ferro Alloys and Minerals Division, Tata Steel Ltd. The views expressed in this article are of the author and not necessarily those of the company he is associated with.