India’s policymakers are making an all-out effort to transform the country into a robust, manufacturing-driven economy. Despite initiatives such as Make in India and the PLI scheme, the manufacturing sector’s share of GDP has stagnated at 15-16%, far below the 2025 target of 25%. A comprehensive manufacturing policy is no longer a choice, but a necessity to address trade deficit, unemployment, and enhance global competitiveness.

India’s merchandise trade deficit exceeds $230 billion annually, with a significant share attributable to imports from China. This trade imbalance highlights the limitations of India’s current manufacturing capabilities and highlights the urgent need to strengthen the domestic manufacturing base. The situation is particularly alarming with China, as India’s industrial sector struggles to compete against Chinese products, which benefit from scale, government subsidies, and advanced infrastructure.

While India enjoys a comparative advantage in labour costs, it remains disadvantaged when it comes to the state-backed manufacturing ecosystem seen in China and other East Asian nations, which have long benefitted from aggressive export strategies and national policies designed to promote manufacturing.

READ I Economic slowdown: A cyclical dip or a deeper malaise

Challenges for Indian manufacturing

Indian manufacturers face numerous challenges that impede their competitiveness. One of the most significant hurdles is the country’s underdeveloped infrastructure. Scattered and unreliable infrastructure — inefficient logistics networks, unreliable power supply, and inadequate industrial facilities — hinders smooth production processes and increases operational costs. These inefficiencies directly affect the competitiveness of Indian manufacturing on the global stage, where it is often more expensive to produce goods in India than in countries like China.

In addition to these logistical challenges, India’s manufacturing sector continues to be held back by limited investment in research and development. India’s R&D spending remains below 1% of GDP, with a significant portion of this coming from the public sector. This is in stark contrast to manufacturing powerhouses like the US, Japan, and Germany, where higher investments in innovation have propelled industrial advancements.

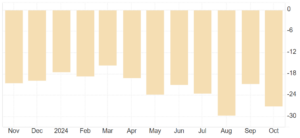

India unemployment rate (%)

India trade deficit ($ billion)

Moreover, India faces a critical skills gap. Despite having a large and diverse talent pool, the country struggles to align its workforce’s capabilities with the needs of modern manufacturing. This disconnect between academia and industry exacerbates the problem, as educational institutions are not adequately preparing students for the technological demands of the manufacturing sector. This skills mismatch, combined with a lack of collaboration between academia and industry, further stifles India’s manufacturing potential.

Another area of concern is India’s heavy reliance on imports for capital goods and advanced technologies. This dependency weakens the country’s manufacturing base, limiting the growth of local capabilities and making India vulnerable to external disruptions in supply chains. The over-reliance on foreign technologies and equipment not only increases costs but also prevents India from building a self-sustaining, globally competitive manufacturing ecosystem.

A manufacturing policy for India

A manufacturing policy tailored to India’s unique challenges and opportunities can provide a strategic roadmap to revitalise the sector. The policy must go beyond basic industrial strategies and focus on fostering economies of scale, reducing import dependence, and enhancing the competitiveness of Indian manufacturers. India must learn from global manufacturing powerhouses, such as China, where state intervention, financial support, and long-term planning have been instrumental in transforming the country into the world’s factory.

State-backed manufacturing systems, which include subsidies, preferential treatment for key industries, and large-scale infrastructure investments, have given countries like China a significant edge in the global market. For India to compete, it needs a similarly proactive and strategic approach to manufacturing development.

During recent pre-budget consultations, economists emphasised the need for a dedicated manufacturing policy to address structural challenges, alongside measures like cold chain storage to tackle food inflation and district-level skilling universities to reduce unemployment. While opinions differed on prioritising consumer demand-led development versus investment and export-led growth, there was consensus on the importance of fiscal flexibility to enable targeted interventions. These insights highlight the urgency of aligning manufacturing policy with broader economic priorities.

Infrastructure development

A successful manufacturing policy for India should begin with a focus on infrastructure development. Reliable, efficient, and modern infrastructure is crucial to reducing operational costs and increasing the global competitiveness of Indian products. The government must invest in creating industrial clusters that integrate the necessary infrastructure for power, transportation, and waste management. This will not only enhance operational efficiency but also create an environment conducive to large-scale manufacturing.

Additionally, there is a need to invest in digital infrastructure that supports the growth of smart factories, enabling Indian manufacturers to adopt advanced technologies like automation and artificial intelligence, which are transforming global production processes.

The policy must also prioritise innovation and R&D. India’s low investment in R&D is a major barrier to industrial growth and global competitiveness. To overcome this, the government should incentivise both public and private investments in research and development. A strong focus on R&D will lead to innovations in manufacturing processes, improve product quality, and reduce reliance on foreign technologies.

Furthermore, bridging the gap between academia and industry is essential. Academic institutions must collaborate closely with industry to ensure that research is aligned with the practical needs of the manufacturing sector. Universities should integrate research-driven projects into their curricula, while also providing training that prepares students for the demands of modern industrial practices.

In addition to infrastructure and innovation, the manufacturing policy must address the issue of skill development. India has a vast pool of young, dynamic talent, but a significant skills gap remains. To bridge this gap, the government should establish skilling universities at the district level, which can provide localised training programs tailored to the needs of the manufacturing sector.

Skilling the workforce

These institutions should be designed to equip students with the necessary technical skills and hands-on experience, making them job-ready for modern manufacturing environments. Moreover, expanding the Prime Minister Internship Scheme and encouraging greater industry participation will also provide valuable practical experience for young professionals.

A comprehensive manufacturing policy should also include measures to reduce India’s import dependency. One approach is to introduce selective tariffs that encourage domestic manufacturing by making imported goods more expensive. For instance, imposing tariffs on the import of laptops could incentivise foreign manufacturers to set up assembly and manufacturing plants in India.

Additionally, the government should continue and expand production-linked incentive (PLI) schemes, which have already shown success in boosting local manufacturing, particularly in sectors like smartphones. The policy should also encourage exports by reintroducing export incentives, which were previously curbed under WTO pressure. Export-driven manufacturing forces industries to meet international quality standards, fostering innovation and improving global competitiveness.

Finally, sustainability must be a key pillar of India’s manufacturing policy. As the global market increasingly values environmentally friendly products, India should encourage green manufacturing practices. This includes adopting energy-efficient technologies, investing in renewable energy sources like green hydrogen, and reducing the carbon footprint of manufacturing processes. By integrating sustainability into manufacturing practices, India can position itself as a leader in eco-friendly production and attract global investment in green technologies.

Need a multi-pronged approach

The government must take a leading role in implementing these policy changes. It can provide fiscal support, invest in infrastructure, and create a conducive regulatory environment that encourages industrial growth. However, the private sector must also step up and play its part by increasing investments in R&D, adopting best practices, and prioritising exports. The collaboration between the government and the private sector will be essential to achieving the ambitious goals set for India’s manufacturing sector.

India’s manufacturing sector must also engage in global collaboration. By forming strategic partnerships with international firms, India can gain access to advanced technologies, expertise in manufacturing processes, and global market access. These partnerships will enable Indian manufacturers to scale up production, improve product quality, and meet international standards. The government’s “Design in India, Design for the World” approach, which encourages innovation tailored to global markets, will be critical in positioning Indian products as competitive on the world stage.

India’s vision of becoming a $30 trillion economy by 2047 hinges on the success of its manufacturing sector. To achieve this, India must develop a comprehensive, forward-thinking manufacturing policy that addresses key challenges such as infrastructure, innovation, skill development, and import dependency.

By adopting a multi-faceted approach, India can build a competitive manufacturing ecosystem that not only drives economic growth but also creates millions of jobs, reduces trade deficits, and establishes the country as a global manufacturing hub. The time to act is now—India must seize the opportunity to transform its manufacturing sector and secure its place as a leader in the global economy.